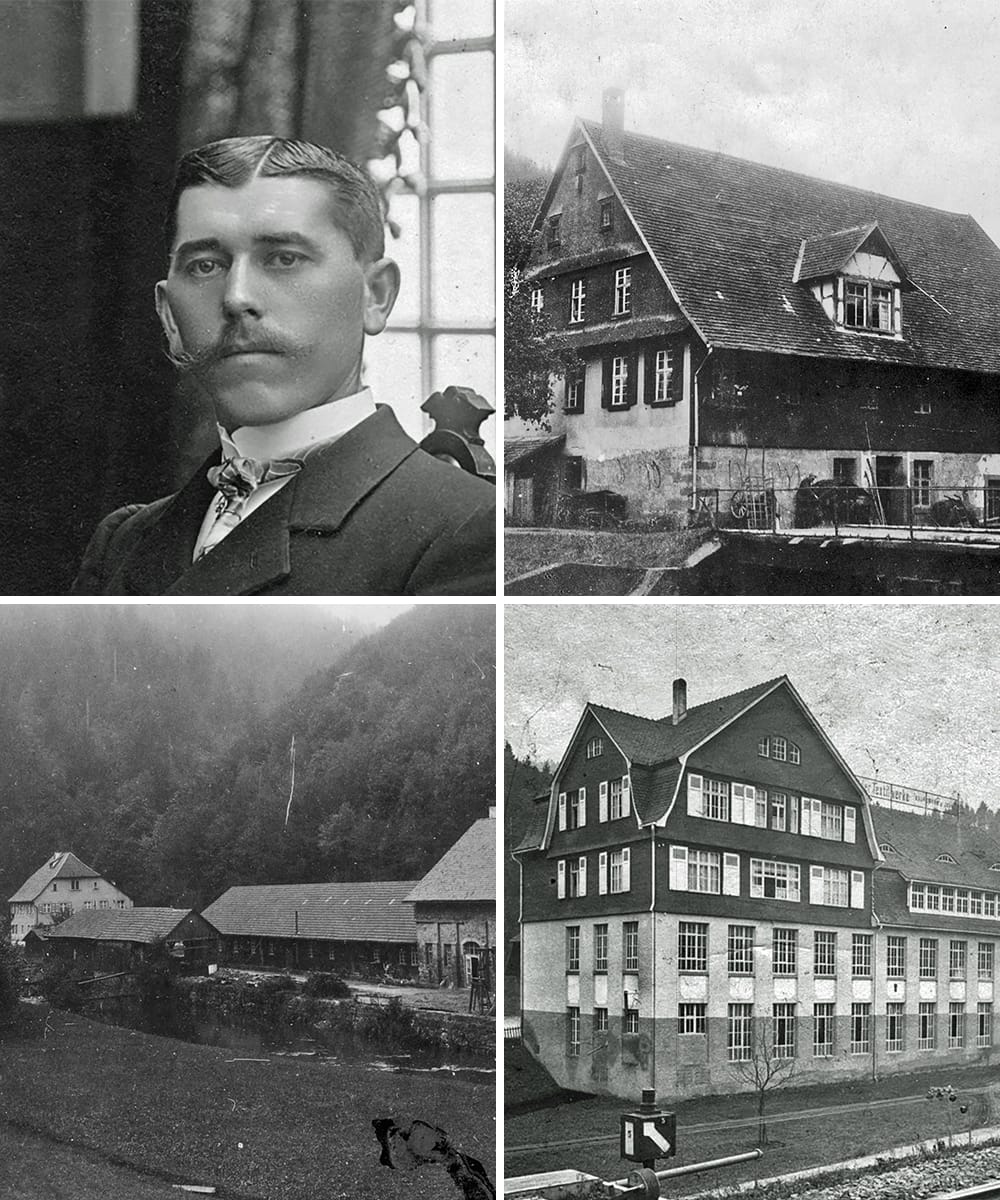

100 years ago Heinrich Kautzmann founded STW and laid the cornerstone for a success story. In the beginning, cotton and shredded fibres were produced, but thanks to the outstanding quality of the fibres, the family business continued to grow and is now managed by the fourth generation of the Kautzmann family.

In 1919 Heinrich Kautzmann founded the "Schwarzwälder Textil-Werke Heinrich Kautzmann" (STW), which operated under this name until 1922 and then for several years was called "Schwarzwälder Textil-Werke Kautzmann & Jahn". The production was first set up in the factories Vortal and Mühle in Bergzell and the production facilities there were taken over by the company Felix Falk. The company premises were leased and only became his property in 1949.

STW's first products consisted of high-quality cotton in bleached and raw white, plain or coloured; made from new jerseys, calico sections or threads. The main field of application for these products was wool for spinning new threads and upholstery wadding.

In 1920, a new turbine system with 340 HP output was installed in the Vortal plant, which was the only way to generate energy at that time. In the first years, the transport from the factories to the railway was carried out by horse-drawn platform trucks. The company itself had two horses and corresponding stables as well as a carriage.

The company Kratzel & Jahn, Mannheim-Neckarau, owner of the "Kunstbaumwollfabrik Schenkenzell", which had rented these factory rooms from the company Sohmer, Schramberg, was located in today's main buildings in Schenkenzell.

On 1st March 1920 Heinrich Kautzmann took over the factory with the obligation to tear the still stored raw materials free of charge over approx. 230 tons, which corresponded to an equivalent value of 110,000 Marks.

The site and the buildings were purchased by the Sohmer company for 300,000 Marks.

The Schenkenzell plant built a bridge with a taxiway track to the railway siding, so that products could be loaded more easily and quickly. Most of the cotton was purchased from the USA and delivered by rail. At the beginning of the 20's the first truck "brand Saurer" with chains driven solid rubber tires was bought.

In 1931 STW had over 20 % of the existing tearing capacity in Germany. Until 1936, 180 employees worked in three shifts.

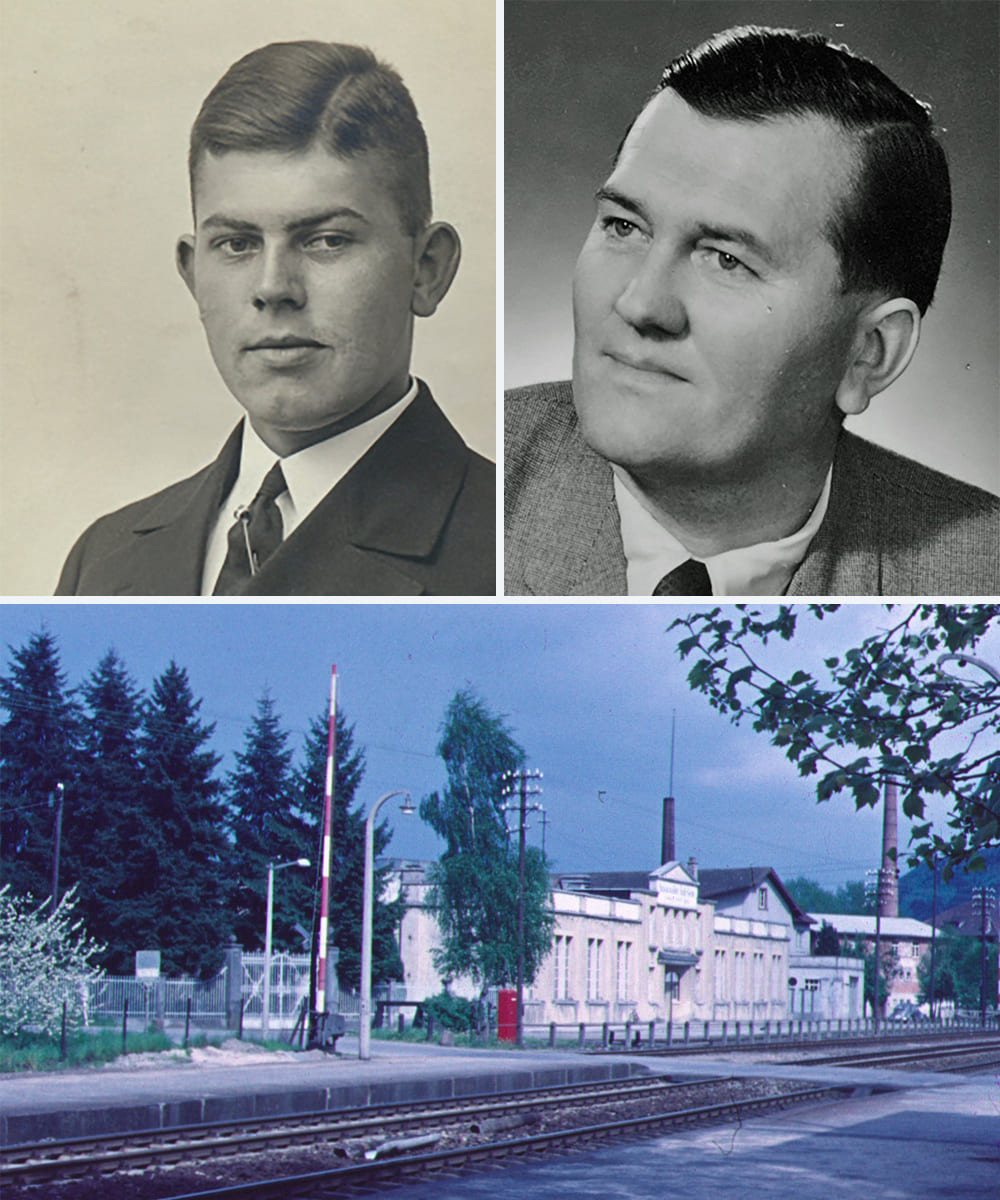

On 1st September 1931 the oldest son of Heinrich Kautzmann, Willy Kautzmann, joined the company.

In 1933 the "Württembergische Kunstwoll-Fabrik" went bankrupt. The Schwarzwälder Textil-Werke Kautzmann & Jahn bought the entire inventory at auction after the foreclosure. As a result, the production of cotton at the Mühle plant was expanded to include specialities.

The specialities of the production at that time were:

· Washing, tearing and bleaching of anatolian wool knitwear and blankets

· Washing, carbonating and tearing of old wool knitwear

· Sorting and tearing of new golf and worsted yarn sections

· Fine preparation by metering was carried out at the Schenkenzell plant

On 1st March 1937 Walter Kautzmann, the second oldest son of Heinrich Kautzmann, joined the company.

In 1938 a further extension as well as the installation of baths for the staff in the turbine building took place. This was very comfortable and not usual at that time.

For their own fire protection, a portable fire pump "Magirus" and a mobile extension ladder "Magirus" were purchased. The operation was carried out by the company's own firefighters, who held regular rehearsals and exercises.

A further milestone in 1938 was the purchase of the Haslach plant in the Kinzigtal with approx. 3,000 m² from the town of Haslach.

The factory in Haslach, which was in a devastating condition in the previous years due to the use by many different companies, was completely renovated in 1938/1939.

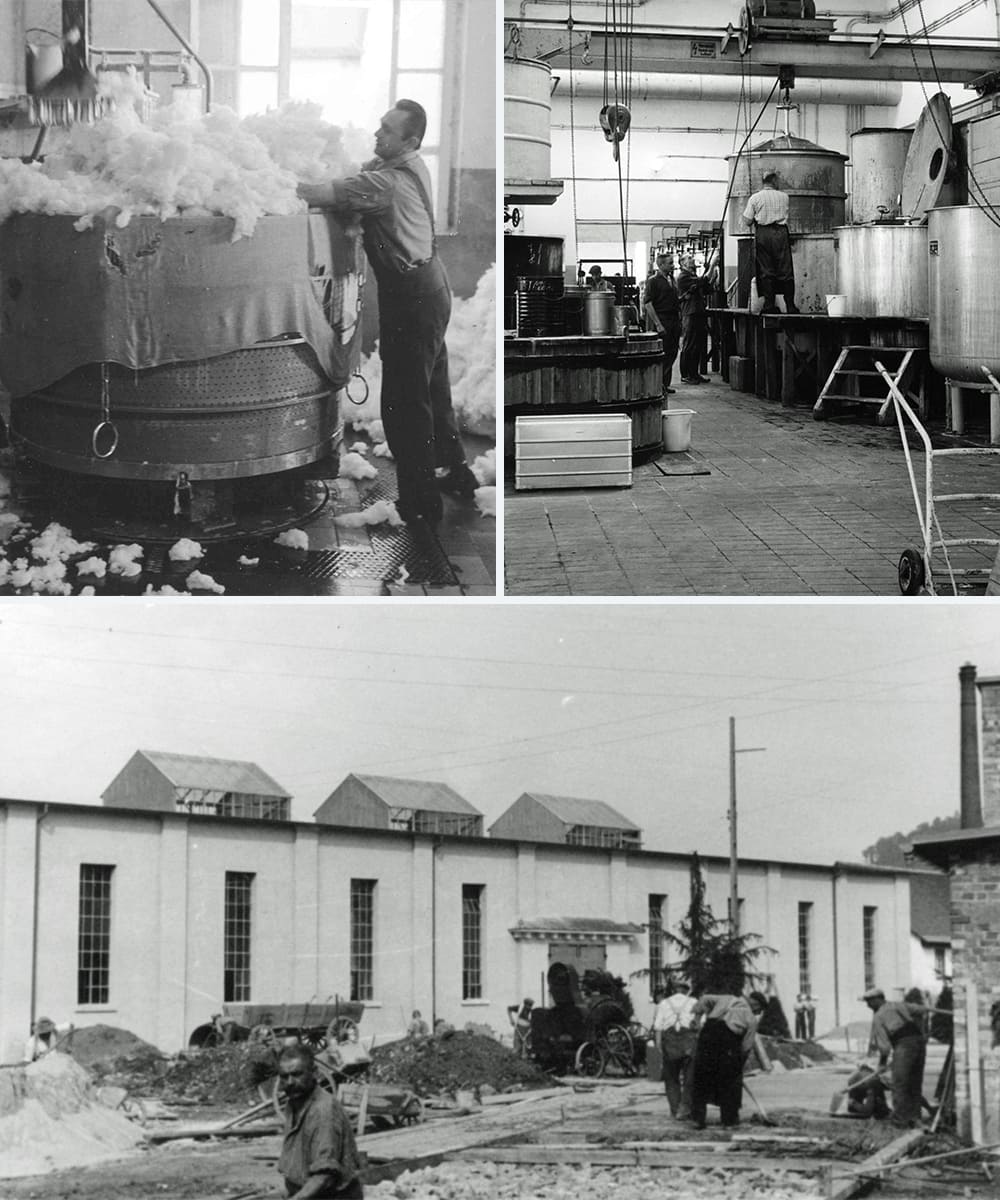

A modern production facility was established. A cotton tearing plant, wool tearing plant and drosing machines were installed and a wool dyeing plant, cotton dyeing plant, laundry and dryer were set up. The dyeing plant from the Vortal plant was relocated to Haslach and integrated into the overall plant.

Since little could be produced during the war years, care was taken to keep the existing machinery in order. This often caused great difficulties, as both raw materials and spare parts were difficult to obtain.

On 12 November 1941, the Office for Wool and Other Animal Hair granted the STW the exclusive right to purchase wool and cotton from Turkey. The aim of this trade agreement was to secure the supply of the cloth and blanket industry for the execution of state orders.

In 1942, a fire-fighting vehicle was purchased for better fire protection.

On 15 November 1942, Otto Kautzmann, the third son of Heinrich Kautzmann, joined the company after he was released from military service as a severely handicapped person after his military hospital stay on 1939.

In 1944 and 1945 the buildings, especially the roofs of the Haslach and Schenkenzell plants, were damaged several times by air raids.

The situation was initially made even more difficult by the occupation after the end of the war. Missing permits and restrictions almost brought the workflow to a standstill. The car park, tools and many other devices were confiscated and removed by the occupying power. For the time being, deliveries were only allowed to the French occupation zone.

In 1947 the company was continued as Schwarzwälder Textil-Werke Heinrich Kautzmann. Two years later, the company was converted into a GmbH (limited liability company).

At the beginning of the 1950s, the dyeing plant was extended by a high-temperature HT dyeing plant at the Haslach plant and served as an addition to the product range.

In the middle of the 50's the company tried to bring the textile raw materials into other sales channels. The first products to be manufactured were small pieces of woven cotton (calico), which were marketed in technical jargon as "cotton chips".

With the fine comminution of the textile fibre "cotton fibre fillers" another product group was added. Production was installed in the intermediate storage facility at the Haslach plant. The machines had to be improved again and again, as everything was more or less built by the company itself.

In 1958, the introduction of the two products "cotton chips" and "cotton fibre fillers" for the thermosetting plastics market was already very successful.

At the end of the 1950s, attempts were made in the dyeing plant to place more emphasis on bleaching cotton noils and similar products in order to open up new sectors for cotton wool and filter factories.

During this period, the last damages caused by the war were repaired on the buildings.

Walter Kautzmann, Managing Director and Head of the plant in Haslach, died in 1962.

In 1963 and 1964 the first short cutting machine for precision short cuts was installed in the Haslach plant. This new technology of fibre shredding made it possible to open up new markets.

The precision short cuts were soon extended to the paint and lacquer industry as reinforcing fibres. In the same area of application, acrylic fibre fillers were used with great success. This made it possible for the first time to reinforce plasters and fillers in such a way that they remained crack-free.

In 1965, senior boss Heinrich Kautzmann died.

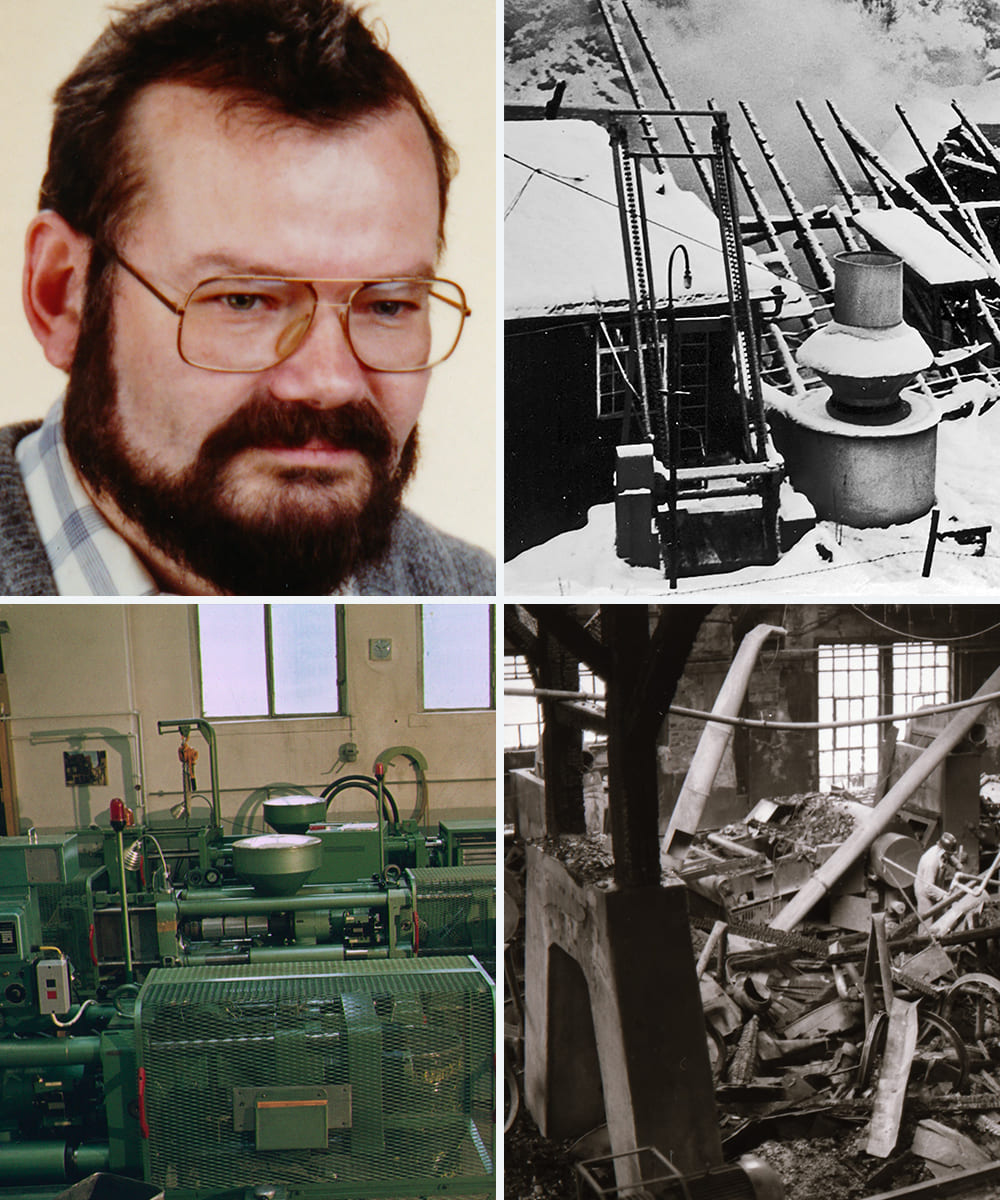

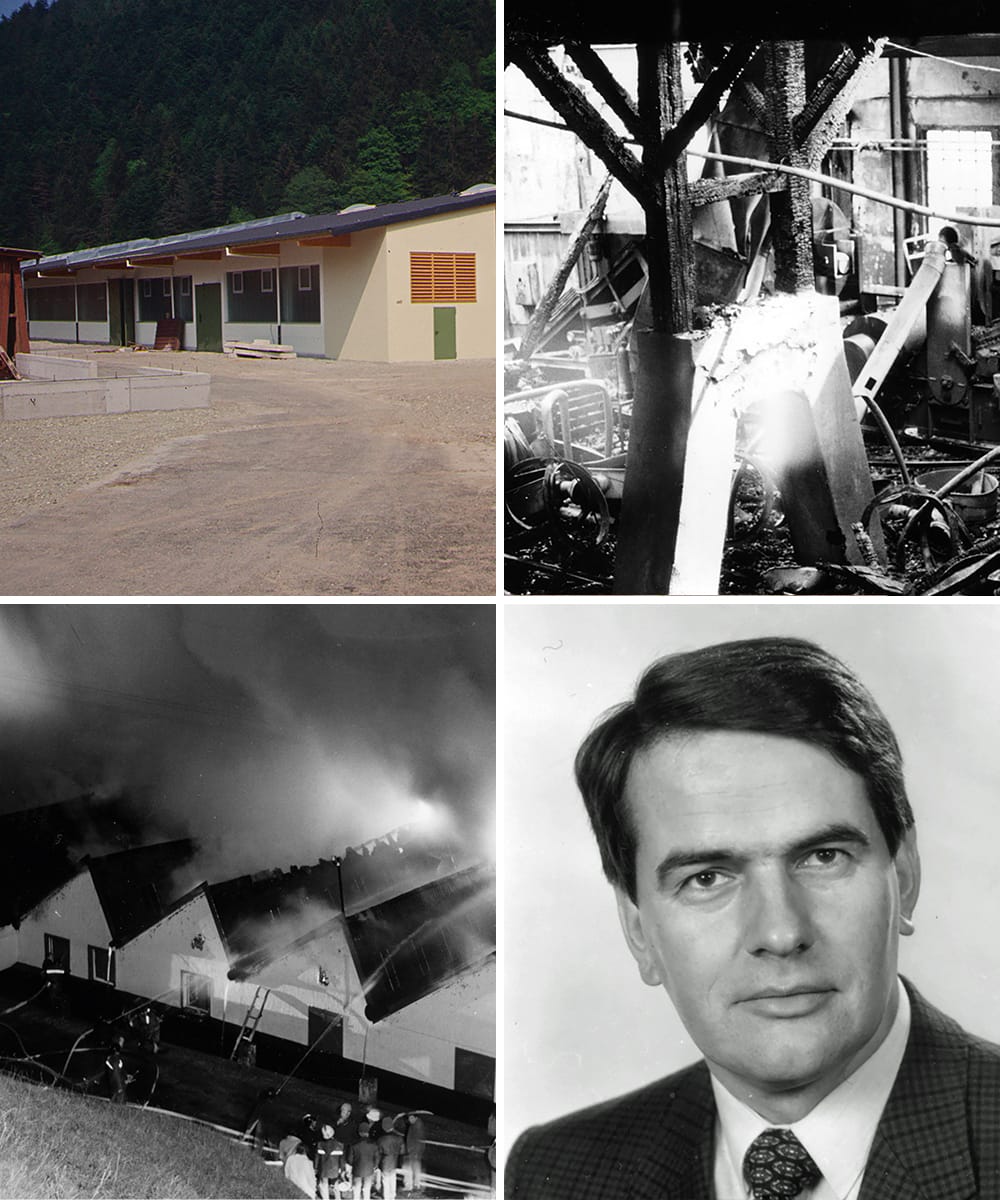

On 18 December 1967, a roof truss fire at the Mühle plant caused by a homeless man who had entered the building, shocked the company. The entire building, including the apartment, burnt down and had to be rebuilt.

The dyeing plant had to be abandoned in 1968 for environmental and cost reasons. The premises of the bleaching, dyeing and drying plants were then rented to the Bebusch company (plastic injection moulding). On 4 December 1969, the two companies agreed on a contract for work and services, which stated that STW would manufacture for Bebusch on a contract basis and in return STW would acquire the know-how for the manufacture of plastic parts. This all led to a new chapter in the company history of Schwarzwälder Textil-Werke Heinrich Kautzmann GmbH. Already at this time the purchase negotiations for own plastic injection moulding machines were in progress.

Werner Kautzmann joined the company on 1st May 1970 to manage the plastic injection moulding department. In 1970, five injection moulding machines and the corresponding accessories were purchased for the injection moulding shop. With these machines, the production of injection moulded parts such as tape cassettes with up to 80,000 pieces per month began.

In 1970 the Managing Director, Willy Kautzmann died.

With the beginning of the plastic injection moulding department, the idea also arose to establish a separate programme for this department and to launch children's toys and handicraft toys on the market. Further development resulted in several toys such as spinning tops, sounding discs, balla-hopp, climbing men and high wheelers.

In 1972 there was an increased demand for exact short cut viscose fibres for the paper industry.

Due to age and production, the tearing mill was generally faced with restructuring. Based on tests with some manufacturers of new shredding machines, the management decided to purchase a new shredding machine. The installation took place in the plant Vortal in the middle of 1972.

On 23 April 1974 the whole building including the new tearing plant was destroyed by a dust explosion caused by stones. A reconstruction permit for the factory at the same location was not approved by the building supervisory authority due to planned road construction. At that time the management decided not to set up a tearing mill after it was no longer usable. This meant the end of the Vortal factory and the products that had been produced since 1919.

On 28 May 1975 the inauguration ceremony of the first expansion stage of the filler building took place. By the new building of 2,000 m² a total working and storage area of 8,200 m² was reached.

Heinz Kautzmann joined the company on 1st September 1976.

On 1st April 1980, Rainer Kautzmann joined the company.

The termination of the production of toy articles and the simultaneous acquisition of further customers for fibre products led to an increase in turnover of 60 % in 1981. In the plastic injection moulding shop at the Haslach plant, only contract manufacturing was carried out. The department for gift articles was dissolved in 1984.

The access road to the Schenkenzell plant was deepened and widened under the railway bridge so that the road could also be used by trucks with semi-trailers. Up to this point, only trucks that were loaded could drive through. When unloaded, these were suspended and pushed through with a forklift truck.

The clientele in the field of brake linings, clutches and similar friction linings has now been intensively worked on, especially with regard to the replacement of asbestos fibres.

In 1986, a pneumatic tube system was installed, which was expanded again and again in the following years and is still used today as an important working tool.

The 25 % decline in sales in 1987 in the construction industry, the largest customer group, was mainly due to the poor construction activity in winter and spring caused by the weather.

In 1989 the 70th anniversary of the company was celebrated in a small circle.

Ab dem Abend vom 14. Dezember waren viele Mitarbeiter aufgrund von Hochwasser im Dauereinsatz. Am Morgen des 15. wurde die Produktion komplett stillgelegt und alle Mitarbeiter für den Hochwasserschutz eingesetzt. Der Pegelstand des Jahrhundert-Hochwassers lag bei 2,90 m. Der Maschinenpark konnte zum größten Teil durch den Einsatz der Mitarbeiter und eigene Maßnahmen gerettet werden.

Im Mai 1991 wurde erstmals in der Firmengeschichte ein Monatsumsatz von 3 Millionen DM überschritten. Das Jahr endete mit einem Umsatzplus von 20 %.

1994 war das Jubiläumsjahr 75 Jahre STW. Am 7. Januar war die Einweihungsfeier für unser neues Kurzschnittgebäude und am 17. Juni feierten wir unser 75-jähriges Bestehen zusammen mit Lieferanten, Kunden und unserem gesamten Personal auf der Festwiese im Betriebsgelände.

1996 liefen umfangreiche Bauarbeiten für ein neues Produktions- und Lagergebäude auf der damaligen Festwiese an. Weiterhin wurde ein Laborgebäude mit Elektrowerkstatt, Staplergarage und großem Versammlungs- und Tagungsraum aufgebaut.

Parallel startete die Entwicklung zur Faserfibrillierung von Aramid über Acryl bis zur Baumwolle oder Jute. Für die STW war dies eine neue Produktionstechnologie mit Wasser und gleichzeitig ein weiteres großes Standbein. Bereits zwei Jahre später wurden im neuen Gebäude Acrylpulp, Aramidpulp und Lyocellpulp hergestellt.

Um den wachsenden Qualitätsansprüchen auch weiterhin gerecht zu werden, wurde ein Qualitätsmanagementsystem nach DIN ISO 9001-94 eingeführt. STW wurde zum ersten Mal im Juni 1998 nach dieser DIN zertifiziert.

Zum Jahresende 2002 wurde die Pulpanlage zur Fibrillierung von Fasern auf die dreifache Kapazität ausgebaut. Somit konnte im Jahre 2002 eine Rekordmenge von 219 t Aramidpulp produziert werden.

Im März 2004 begann sich das Gesicht des Standortes STW nochmals zu verändern. Es begannen die Abbrucharbeiten der Garagen, des Luftschutzbunkers, eines Wohnhauses und des Musterzimmers. Anschließend erfolgte der Neubau einer Kurzschnittproduktionshalle, eines Versandlagers und weiterer Lagermöglichkeiten.

Im Dezember 2005 wurde das Lagergebäude zusammen mit allen Handwerkern, Betriebsangehörigen, Vertretern der Gemeinde und Gesellschaftern bei einer Weihnachtsfeier gebührend eingeweiht.

Ein sehr großer Hersteller von Teebeutelpapieren in England wurde 2006 zahlungsunfähig und musste Insolvenz anmelden. Dies bedeutete für die STW einen Schaden von weit über ½ Mio Euro.

Ausgelöst durch die Wirtschaftskrise, die im August 2008 begann, verzeichnete die STW einen massiven Umsatzeinbruch. Bei allen Maßnahmen, die ergriffen wurden, um möglichst verlustfrei durch die Krise zu steuern, stand der Mitarbeiter immer im Vordergrund. Ohne Mitarbeiter-Entlassungen war Mitte 2009 der Auftragseingang wieder auf das Niveau vor der Krise angewachsen.

Am 10.01.2009 verstarb Senior-Chef Otto Kautzmann im Alter von 92 Jahren.

Im Mai 2009 schied Heinz Kautzmann aus dem Unternehmen aus. Harald Kautzmann, Bruder von Rainer Kautzmann, der bereits im September 2008 in das Unternehmen eingetreten ist, übernahm daraufhin die Personal- sowie die Finanzleitung.

In 2011, the "Insel" property in Schenkenzell, located between Reinerzau and Kinzig, was purchased in order to be able to build the newly required fish ladder. It was always important for STW to continue operating all available hydroelectric power plants in order to use green energy.

On 1st April 2015 Frank Kautzmann and Nico Kautzmann were hired as the future successors of Harald Kautzmann and Rainer Kautzmann. On 1st March 2017 they were appointed as managing directors.

Rainer Kautzmann left the company at the turn of the year 2017/2018.

Due to a massive warehouse bottleneck in Aue 3, the construction of a new warehouse building with 5,600 m² of space at the old Mühle site started in 2017. With the completion in May 2018, the inauguration was duly celebrated with the staff.

A new product development was completed in 2018. With a combination of temperature stability and high fibrillation, our new DIMAXA® polyacrylic pulp series is mainly used in paper and filtration applications. Equipped with the ISEGA certificate, DIMAXA® can also be used in the food industry.

The old office building was completely renovated in December 2018. Completely new workplaces, new IT and state-of-the-art media technology ensure a pleasant working atmosphere and set the stage for a paperless office and work in accordance with Industry 4.0.

In July 2019, STW celebrated its 100th anniversary at the Schenkenzell location.