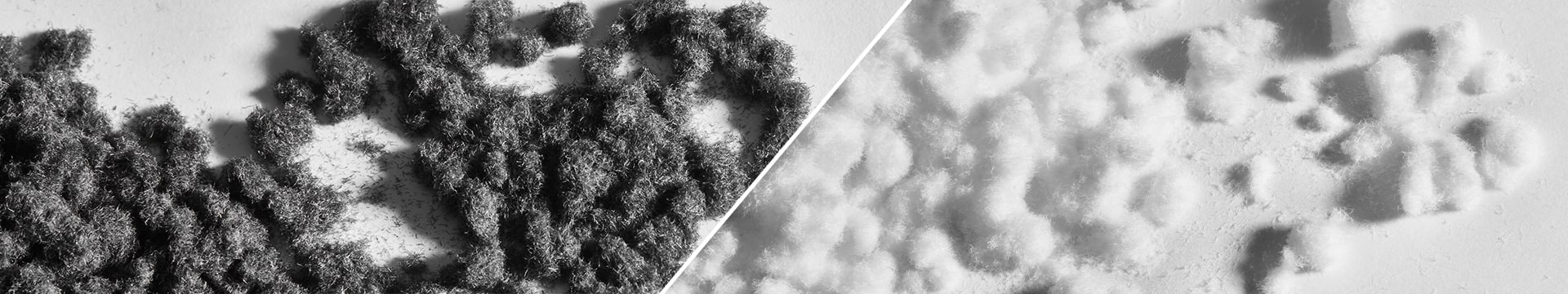

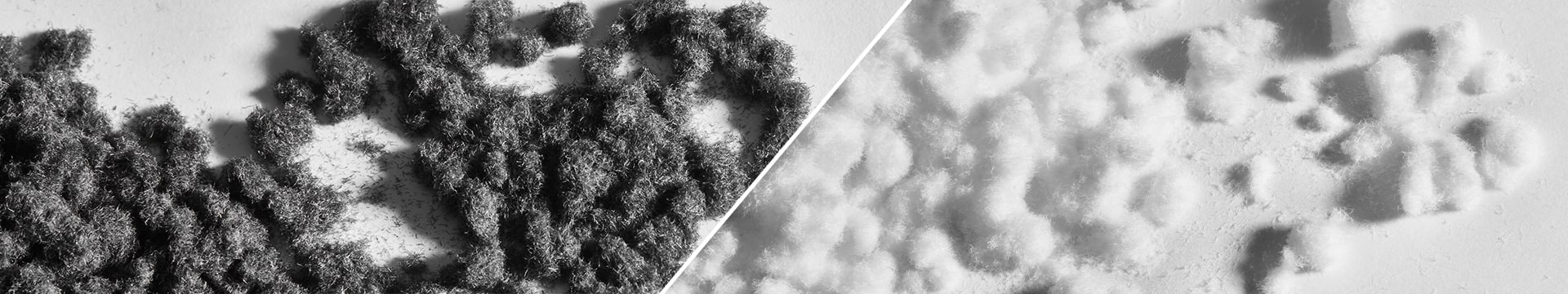

Its excellent properties and resulting wide distribution make cotton the most important natural textile fibre. Cotton fibres are obtained from the seed hairs found in the fruit of the cotton plant. These natural fibres feature a high purity with a cellulose content of approx. 95 %. Cotton is processed into yarns, threads as well as fabrics, and used in textiles, furniture and other industrial products. The properties and surface of the cotton can be significantly affected by the refinement of the cotton yarn. Aside from the widespread offering as fabric or yarn, STW offers hydrophilic and hydrophobic cotton for use as fibre filler.

Advantages

Disadvantages

After harvesting, the baled cotton is delivered directly to spinning mills. Here, the fibres are separated lengthwise, whereby long fibres are used for textile production and short fibres for cellulose production. The fibres are then carded and processed into yarns. Depending on the requirements of the application, the yarn can be refined in further work steps. This makes it possible, for example, to produce hydrophobic cotton which, contrary to its natural properties, absorbs water only very slowly.

Fibre Filler

29

Types

Short Cut

2

Types

Contact our fibre experts and discover our extensive STW sample box with numerous raw material samples, personally tailored to your needs and requirements.

State-of-the-art laboratory facilities, quality management according to ISO 9001:2015, energy management according to ISO 50001:2018 and last but not least the high demands on our own work ensure the high quality standards of our Cotton fibre. See for yourself.

If you want to know more about the technology and quality of our Cotton fibre If you want to know, just get in touch with us. We would be happy to advise you comprehensively and help you with our know-how.

You are looking for the perfect Cotton fibre for your application or have an exact requirement profile, which the used Cotton fibre must fulfill?

Then you are exactly right, as a technology leader in the field of fiber development and production, we offer you individual solutions and manufacturing processes that ensure constant and reproducible fiber quality.