VIP stands for Vacuum Insulation Panel. The principle is similar to that of a Thermos flask: Specially shaped, porous blocks of material with a low heat transfer coefficient are welded into an aluminium composite foil and vacuum-sealed before closure.

Our fibres help to keep the material matrix, which also consists of silicic acid, together. The special surface structure of our fibres supports the technical effect.

The vacuum provides a very efficient high-performance insulation layer that greatly reduces cold or heat transfer.

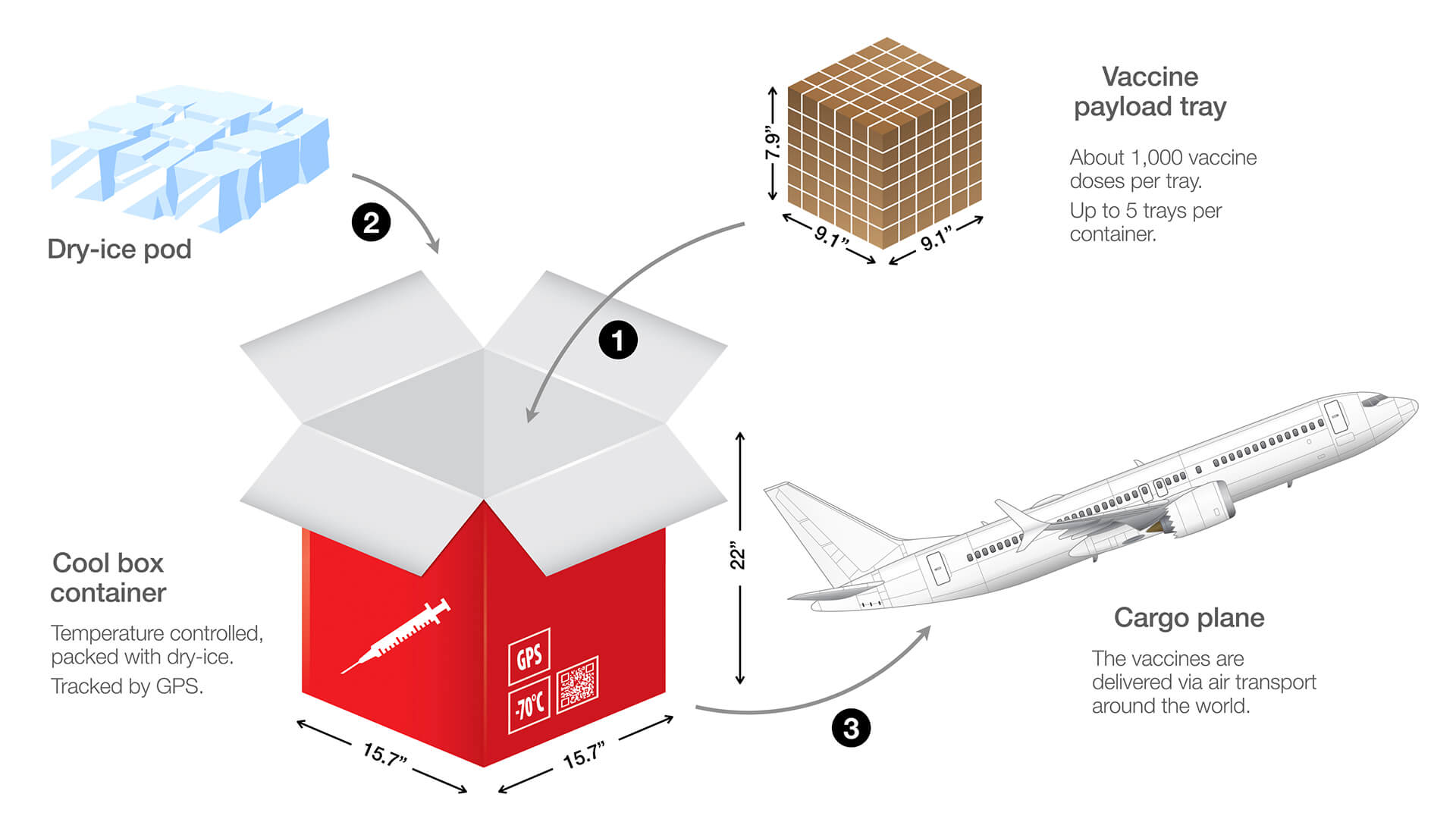

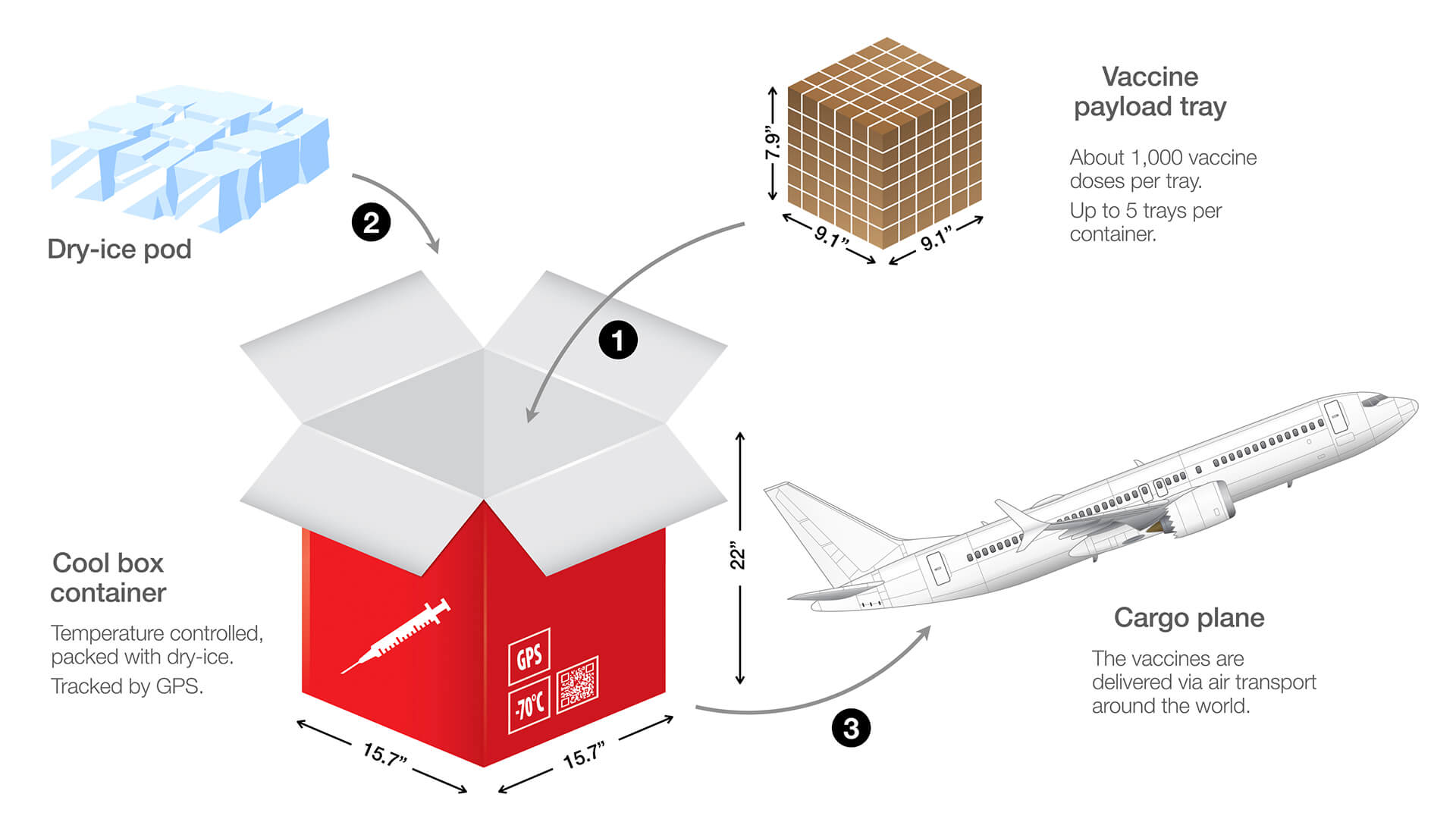

These plates are used, for example, in fridge and freezer combinations, cool boxes for the transport of the corona vaccine, containers for the transport of organs, refrigerated vehicles, passenger compartments, special containers, building façades, and many others.

The insulating effect is 5–10x higher than the possible effect that can be achieved with conventional insulating materials. This enables objects such as refrigerators to be designed with a smaller footprint.

It is important for the long-term function that the vacuum is maintained. There are panels, therefore, that are equipped with a monitoring sensor (RFID) and that can be read from the outside. This allows the panels to be monitored and replaced if necessary.

VIP's make an important contribution to energy saving and the reduction of CO2 emissions.

Fibre recommendation